The Spline Hammer Bit

What is a Spline Bit?

When a post-installed concrete anchor is being used to attach a fixture to cured concrete, a hole must be drilled in the concrete. The bit one chooses to use for this purpose is typically dependent upon the type of hammer drill being used. The spline hammer bit gets its name because it has a spline shank (meaning it has 12 "teeth") that fits into the spline drive of the hammer drill.

When a post-installed concrete anchor is being used to attach a fixture to cured concrete, a hole must be drilled in the concrete. The bit one chooses to use for this purpose is typically dependent upon the type of hammer drill being used. The spline hammer bit gets its name because it has a spline shank (meaning it has 12 "teeth") that fits into the spline drive of the hammer drill.

How is a Spline Bit Made?

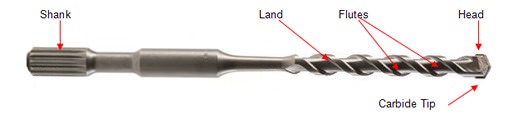

Spline hammer bits are made up of 4 distinct parts. These parts include:

- The shank: The spine hammer bit has 12 "teeth", or splines that fit into the hammer drill collar. These shank bits are held to exact tolerances to assure a perfect fit into the hammer drill.

- The land: The land is the raised portion of the spiral (similar to the crest or peak of a wave).

- The flute: This can also be considered the trough section of the spiral. The flute facilitates the removal of the concrete dust as the hole is being drilled.

- The head and carbide tip: These 2 parts work together to break up the concrete. The carbide is brazed onto the head to harden the tip of the spline bit to assist in the breaking of the concrete.

Spline drive hammer bits are milled from a single piece of steel to provide maximum life. Spline drill bits are held to exacting tolerances to assure a perfect fit as well as maximum impact and torque transmission.

How is a Spline Bit used?

Spline bits are designed for use with a rotary hammer drill with a spline drive. The spline bit is placed into the end of the drill and is held in place with a retaining pin that engages just below the spline section of the shank.

The hammer drill should only be used in the hammer/rotation position when using a Spline bit to drill into concrete. The bit will rotate and impact at the same time. It is important to push only with enough force to keep the bit from bouncing. While extra force may assist in standard drilling operations, it will have a negative effect on the drilling process when drilling into concrete. Too much pressure may cause the spline bit to break off or bind up in the hole.

If the bit binds up in the hole, simply reverse the hammer drill and attempt to back the bit out of the hole. If unsuccessful, it may be necessary to use a wrench to remove the bit. Again, do not use excessive force when attempting to remove a bound up bit. The most important tool used when removing a bit is patience!

The spline hammer bit rotation is typically about 300-400 RPMs. This is a lot slower than other types of masonry drill bits that can rotate at speeds of 600-650 RPMs. This results in debris moving down the flutes at a slower rate and increases the likelihood of the spline bit getting jammed in the hole. To minimize jamming due to excessive dust, occasionally withdraw the bit while drilling to aid in the removal of the concrete dust. Always make sure that the bit stops rotating before it is pulled out of the hole. This helps maintain the integrity of the hole.

When should a Spline Bit be used?

A hole is typically drilled into concrete for one of two reasons. The first reason to drill a hole into concrete, brick or block is for the installation of a concrete fastener. The second reason is to create a path for the installation of wiring or plumbing.

When using a spline bit to drill into a wall, it is important to support the weight of the hammer drill itself. If the drill does not receive the proper support, the bit will end up carrying a portion of the weight. This may cause undue pressure on the flute of the bit and could possibly cause the drill bit to break in the hole.

Below is a chart indicating the available sizes and corresponding drilling depths for spline hammer bits.

|

Bit Size dia. x OAL* |

Usable Length (or) Drilling Depth |

Bit Size dia. x OAL* |

Usable Length (or) Drilling Depth |

|---|---|---|---|

| 3/8" x 10" | 4" | 11/16" x 12" | 6" |

| 3/8" x 12" | 6" | 11/16" x 23-1/2" | 18" |

| 3/8" x 18" | 12" | 3/4" x 12" | 6" |

| 7/16" x 123" | 6" | 3/4" x 18" | 12" |

| 7/16" x 14" | 7" | 3/4" x 23-1/2" | 18" |

| 1/2" x 12" | 6" | 27/32" x 13" | 7" |

| 1/2" x 18" | 12" | 27/32" x 23-1/2" | 18" |

| 1/2" x 23-1/2" | 18" | 7/8" x 12" | 6" |

| 1/2" x 30" | 24" | 7/8" x 18" | 12" |

| 1/2" x 36" | 30" | 7/8" x 23-1/2" | 18" |

| 1/2" x 48" | 42" | 7/8" x 36" | 30" |

| 9/16" x 12" | 6" | 1" x 12" | 6" |

| 9/16" x 18" | 12" | 1" x 18" | 12" |

| 9/16" x 23-1/2" | 18" | 1" x 23-1/2" | 18" |

| 9/16" x 30" | 24" | 1-1/8" x 12" | 6" |

| 9/16" x 36" | 30" | 1-1/8" x 18" | 12" |

| 9/16" x 48" | 42" | 1-1/8" x 23-1/2" | 18" |

| 5/8" x 12" | 6" | 1-1/4" x 18" | 12" |

| 5/8" x 18" | 12" | 1-1/4" x 23-1/2" | 18" |

| 5/8" x 23-1/2" | 18" | 1-3/8" x 18" | 12" |

| 5/8" x 30" | 24" | 1-3/8" x 23-1/2" | 18" |

| 5/8" x 36" | 30" | 1-1/2" x 18" | 12" |

| 1-1/2" x 23-1/2" | 18" |

* OAL stands for Over All Length

It is important not to drill a hole deeper than the intended drilling depth of the bit being used. This could cause an interruption in dust removal and increase the amount of heat on the carbide tip. Heat buildup on the carbide may melt the brazing material, causing the carbide plate to move. Movement of the carbide plate could lead to the bit failing to break the concrete.

Some suggestions for increasing the life of Spline Drill Bits:

- Before drilling, check that the carbide tip is in good shape.

- Visually inspect the flutes and land of the bit to ensure that there is no damage from previous drilling jobs.

- Let the tool do the work. When used in a quality hammer drill, the spline bit will cut into concrete with relative ease. Hold the drill level and apply pressure evenly throughout the hole drilling process.

The primary advantage of the spline shank hammer bit is its maximum drilling torque. The spline shank bit requires the use of a spline drive hammer drill.

Recent Posts

-

Best Masonry Anchors

Get the job done right the first time by using the best masonry anchors for the application. A mason …Nov 24th 2020 -

Best Cinder Block Fasteners

Fastening to Cinder Block Cinder block …Jun 16th 2020 -

Best Brick Anchors

Male or Female Anchor? Female anchors would require the spotting of the anchor and then place th …Feb 21st 2019