Rules for Fastening to Concrete

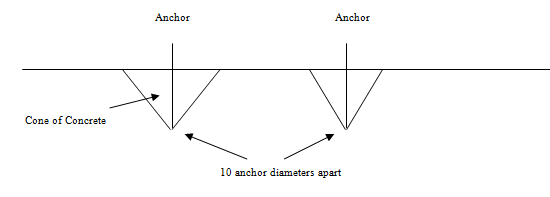

Rule: Concrete fasteners should not be set closer than 10-anchor diameters from each other.

Explanation: Mechanical type concrete anchors exert outward pressure against the wall of the hole in concrete. This pressure goes out and up the length of the anchor forming what is commonly called a cone of concrete, as it is cone-shaped in appearance. Since anchors derive their holding values from the base material, this cone-shaped area is a picture of the holding values the anchor has. Placing anchors closer than 10 anchor diameters apart will allow the two anchors' holding values to overlap. This overlapping will decrease the holding values of both anchors as pictured below:

10 Anchor Diameter Minimum Spacing

Less Than 10 Anchor Minimum Spacing

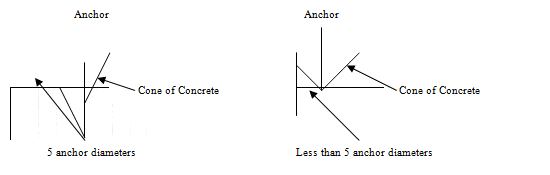

Rule: Mechanical type anchors should not be set a minimum of 5 anchor diameters from an unsupported edge.

Explanation: If set too close to an unsupported edge, the outward pressure of the concrete anchor will decrease the holding value of the anchor or make it non-existent. This is also known as a "blowout" of the base material.

Rule: When drilling a hole into concrete, brick or block base material- the hole must be drilled 1/2" deeper than the concrete anchor will penetrate.

Explanation: The extra depth of the hole will ensure that the anchor does not bottom out and will allow space for any dust that may be created in the drilling process. If the anchor is being placed at minimum embedment requirements, the extra space will make sure that the minimum amounts are met.

Rule: Each anchor has a minimum embedment to which it must be placed in order to create the holding values for the anchor.

Explanation: Each anchor has a minimum embedment (into the base material) that must be reached in order for the anchor to achieve its holding values. The minimum embedment depth is different for each anchor and each diameter. See next rule for the exception to this rule.

Rule: Tapcon® concrete screws have a minimum embedment of 1" for both the 3/16" and 1/4" diameter and a maximum embedment of 1-3/4".

Explanation: Tapcons cut threads into the base material. The lead thread does all of the cutting and will become ineffective after reaching 1-3/4" embedment.

Rule: When drilling holes for anchors to be used in concrete, brick or block- a hammer drill should be used.

Explanation: Drilling into concrete, brick or block requires that the material is broken up and removed from the hole. This is different than working with metal or steel since these materials require that the material is cut and removed. The hammer motion breaks up the base material and the rotation of the hammer drill removes the debris from the hole.

These rules will aid in the safe and correct installation of concrete fasteners for your application. Please remember that these are just "rule of thumb". Other safety precautions such as engineering guidelines and safety gear should also be taken into consideration.

Recent Posts

-

Best Masonry Anchors

Get the job done right the first time by using the best masonry anchors for the application. A mason …Nov 24th 2020 -

Best Cinder Block Fasteners

Fastening to Cinder Block Cinder block …Jun 16th 2020 -

Best Brick Anchors

Male or Female Anchor? Female anchors would require the spotting of the anchor and then place th …Feb 21st 2019